Reverse – Engineering: Efficiency, Innovation, and Competitiveness

In today’s industrial landscape, characterized by rapid technological changes and evolving customer needs, reengineering has become a strategic lever to ensure a company’s competitiveness. Reengineering involves the radical redesign of production processes to improve efficiency, effectiveness, and flexibility, adapting to new technologies and market demands. In this blog, we explore the advantages of reengineering and how R.D.D. Italia supports brands in transforming their production processes to create value.

Reengineering: What It Is and Why It Matters

Reengineering is based on a complete overhaul of the production process, aiming to optimize resources, reduce waste, increase quality, and improve sustainability. This approach goes beyond simple technological upgrades; it implies a rethinking of operational methods, introducing innovations that may include automation, artificial intelligence, and real-time data analytics. For companies, this means greater adaptability and resilience in facing competition.

Embracing New Technologies: The Foundation for Innovation

To keep pace with the demands of an increasingly digital market, companies must integrate advanced technologies that render traditional solutions obsolete. For example, automating manual operations drastically reduces human error and operating costs while boosting speed and precision. This not only makes processes more efficient but also frees human resources that can be redirected to higher-value tasks, such as supervision, quality control, or maintenance management.

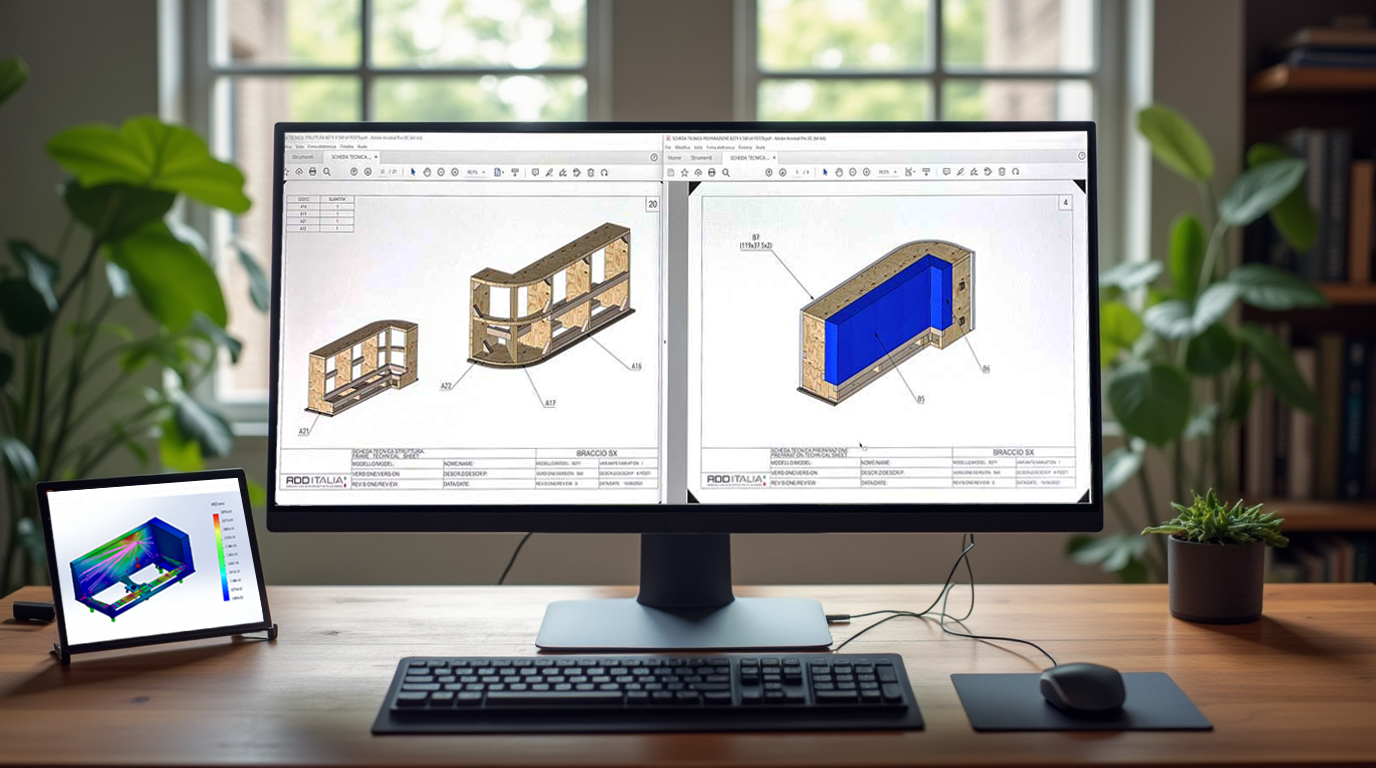

For R.D.D. Italia, reengineering production processes also includes advanced robotics, artificial intelligence, and predictive analytics, elements that help optimize production flow and reduce downtime.

Overcoming Technological Obsolescence to Stay Competitive

Technological obsolescence is a constant challenge for the industry. When technology no longer meets efficiency, quality, or safety standards, it becomes a burden on the company. Reengineering offers an integrated solution: it allows the update of production processes with modern technologies, improving performance and reducing costs. Replacing outdated equipment with cutting-edge solutions enables companies to shorten production times and achieve a final product that meets market expectations.

For R.D.D. Italia’s clients, this means benefiting from a strategic partner who guides them in adopting new technologies to maintain a leadership position.

Product Evolution and Process Adaptation: Strategic Flexibility

With the introduction of new product variants or additional components, it is often necessary to modify existing production processes. R.D.D. Italia supports brands in designing production lines that can quickly adapt to product changes, for example, by adding new assembly phases or implementing technologies like 3D printing.

This type of production flexibility is crucial for companies operating in dynamic sectors, as it allows them to respond swiftly to market demands without compromising product quality.

Objectives of Reengineering: Efficiency, Quality, and Sustainability

Why embark on a reengineering project? The main objectives can be divided into four key areas:

- Operational Efficiency: Reduce production times and costs through automation and advanced technology. Eliminating waste allows for optimal resource use.

- Enhanced Quality: New automated control systems ensure uniform quality, reducing defects and increasing consistency in production.

- Flexibility and Adaptability: The ability to quickly respond to market changes and new product requirements is essential for maintaining competitiveness.

- Environmental Sustainability: Optimizing production processes reduces energy and raw material consumption, enabling companies to operate more sustainably and minimize environmental impact.

R.D.D. Italia adopts a holistic approach to reengineering, considering not only operational benefits but also those related to sustainability and environmental impact.

Challenges of Reengineering: How to Overcome Them

Although the advantages are clear, reengineering also presents challenges. This process requires an initial investment of time, resources, and personnel training. R.D.D. Italia guides companies throughout the journey, from preliminary analysis to full implementation, with particular attention to change management.

A common obstacle is internal resistance to adopting new technologies and methods. To overcome this, R.D.D. Italia engages company teams from the early stages of the project, demonstrating tangible benefits and supporting a gradual yet effective transition to new production models.

R.D.D. Italia’s approach to reengineering is holistic, accounting for both operational and sustainability gains. For R.D.D. Italia’s clients, this means having a strategic partner who guides them in adopting new technologies to maintain a leadership position.

Conclusion: Why Reengineering is a Strategic Choice for Companies

In summary, reengineering is an essential strategy for companies that want to remain competitive and quickly adapt to market changes. Through production process optimization, R.D.D. Italia helps its clients achieve tangible results in terms of efficiency, quality, and sustainability. Thanks to R.D.D. Italia’s expertise, brands can embark on this journey with the assurance of being supported by a solid partner with a forward-looking approach.

In a rapidly evolving global market, reengineering is an invaluable asset for companies aiming to stand out for excellence, innovation, and environmental responsibility. With R.D.D. Italia’s expertise, brands can approach this process with the confidence that they are working alongside a trusted and future-oriented partner.

Share this post

Latest posts

7 March 2025

7 March 2025