Bando Disegni+ 2024: Up to 80% Non-Repayable Grants to Recover Expenses!

The Bando Disegni+ 2024 represents an extraordinary opportunity for Italian micro, small, and medium-sized enterprises (SMEs) that wish to enhance their industrial designs and models. With non-repayable grants covering up to 80% of eligible expenses, the call supports companies in transforming innovative ideas into successful market products.

In this article, we will outline the key points of the call and how R.D.D. Italia can be your essential partner, guiding you step by step in submitting your application and implementing the project.

What is the Bando Disegni 2024

Promoted by the Ministry of Enterprises and Made in Italy and managed by Unioncamere, the Bando Disegni 2024+ aims to support Italian companies in enhancing registered industrial designs and models. The incentives are granted in the form of capital contributions, with a total budget of 10 million euros.

Who Can Participate

SMEs that meet the following criteria can apply:

- Legal and Operational Headquarters in Italy: Companies must be based and operate within Italy.

- Regularly Established and Active: Must be officially registered and currently active.

- Ownership of a Registered Design or Model:

- Registered from January 1, 2022, at the UIBM, EUIPO, or WIPO (with Italy designated).

- Compliance with Obligations:

- Up to date with social security contributions.

- Not undergoing insolvency procedures.

Offered Incentives

- Non-Repayable Grants covering up to 80% of eligible expenses, with a maximum of 60,000 euros per company.

- Increased Percentage: Up to 85% for companies with gender equality certification.

- Financing of Specialized Services for the enhancement of designs and models.

How R.D.D. Italia Supports Companies

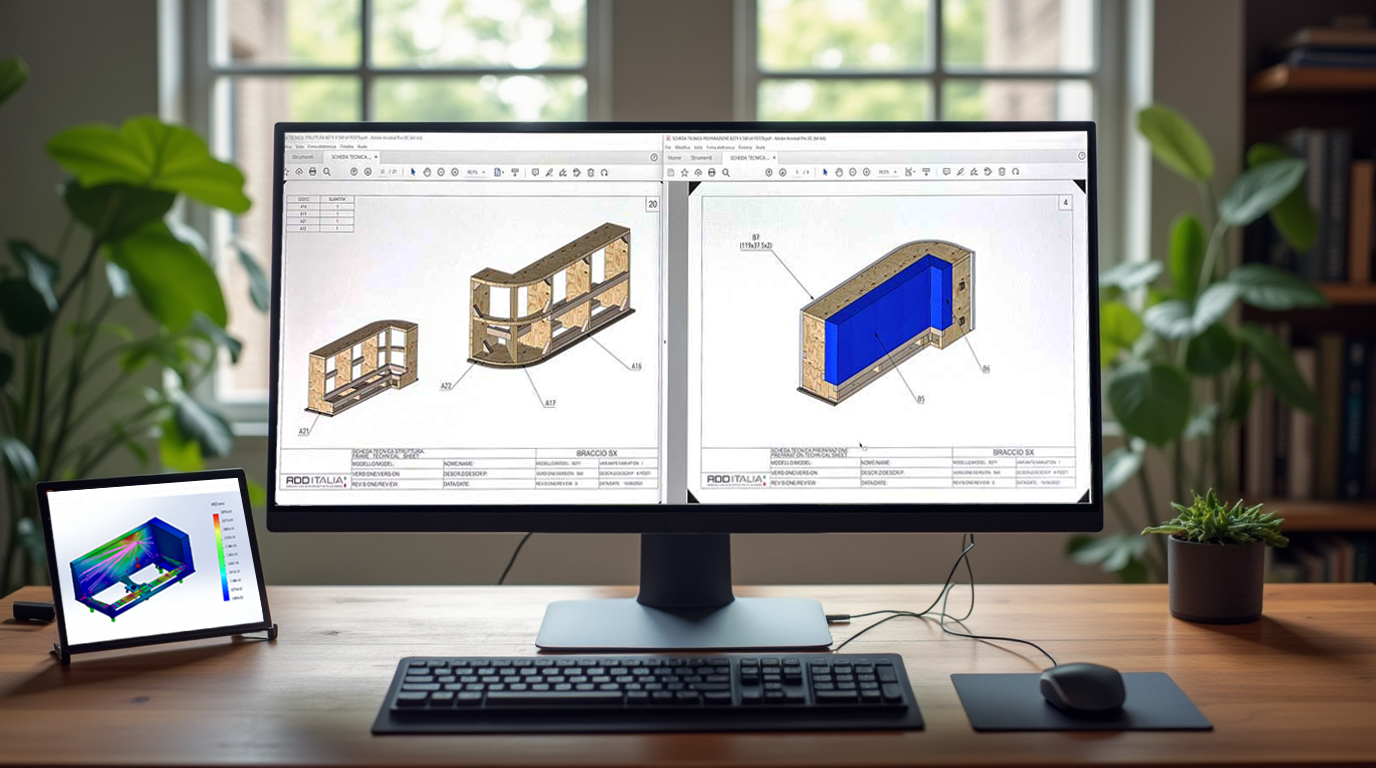

R.D.D. Italia positions itself as an essential intermediary in the process of participating in the Bando Disegni+ 2024, offering comprehensive and personalized support. Our experience allows us to guide you through the peculiarities of the call, ensuring that your application is presented effectively and meets all required criteria.

How We Can Help You

- Application Preparation

- Preliminary Analysis: We assess and develop the eligibility of your design or model.

- Documentation: Assistance in collecting and compiling all necessary documents.

- Project Plan: Collaboratively develop a detailed and compelling project plan.

- Management of Call Specificities

- In-Depth Knowledge: Up-to-date with all specifics and updates of the call.

- Avoiding Common Errors: Preventing causes of exclusion by ensuring a complete and correct application.

- Timelines: Guarantee adherence to deadlines, crucial for application acceptance.

- Project Implementation

- Fundable Services: We directly offer the services subsidized by the call:

- Creation of Prototypes and Molds

- Technical Consultancy for Production

- Support for Product Certifications and Environmental Sustainability

- Consultancy for Market Approach

- Coordination: Managing all project phases to ensure consistency and quality results.

Why Choose R.D.D. Italia

- Experience and Professionalism: Years of industry experience make us a reliable partner.

- Integrated Service: A single point of contact for all needs, from application to implementation.

- Personalized Approach: Tailored solutions based on your company’s specific requirements.

- Increased Chances of Success: A well-prepared application has a higher likelihood of obtaining the grant.

Contact Us for a Consultation

- Email: info@rdditalia.com

- Phone: +39 080 222 1886 | +39 080 523 9158

- Address: Via delle Cappelle, 77, 70022 Altamura BA

Let R.D.D. Italia assist you in making the most of the Bando Disegni 2024+ and transforming your innovative designs into market successes. Contact us today to begin your journey towards growth and innovation!

Share this post

Latest posts

14 September 2025

14 September 2025

14 September 2025

14 September 2025

14 September 2025